Leave Your Message

In the world of formulation science, the role of an Emulsifying Solubilizer is critical. These compounds help ensure that ingredients blend smoothly, creating stable and appealing products. According to a report by MarketsandMarkets, the emulsifiers market is projected to reach USD 25 billion by 2025, highlighting their importance across various industries.

Dr. Emily Foster, a leading expert in formulation chemistry, emphasizes this point: "The right emulsifying solubilizer can transform even the simplest formulations into exceptional products." Manufacturers strive to find the perfect balance between functionality and stability in their formulations. However, achieving this balance often comes with challenges.

Despite advancements, many formulations still struggle with stability issues or separation over time. This complex relationship between ingredients can lead to consumer dissatisfaction. The quest for the ideal Emulsifying Solubilizer remains a journey—one filled with trial and error. Manufacturers must reflect on their current approaches and remain open to innovative solutions.

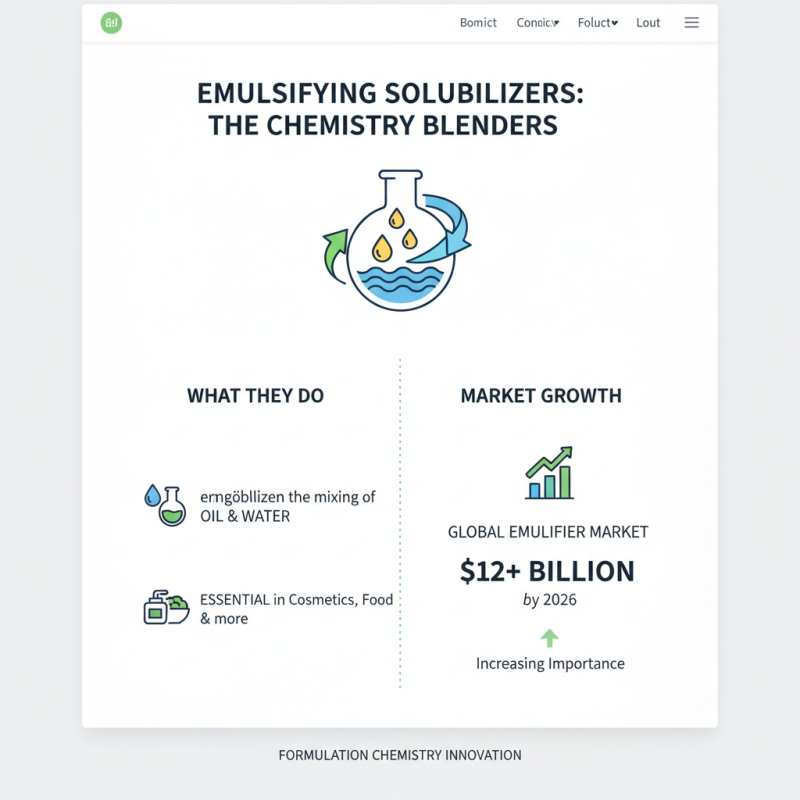

Emulsifying solubilizers play a crucial role in formulation chemistry. These compounds help blend ingredients that typically do not mix, such as oil and water. Their inclusion is essential in products ranging from cosmetics to food. Reports indicate that the global emulsifier market is projected to reach over $12 billion by 2026. This growth highlights the increasing importance of effective formulation practices.

Choosing the right emulsifying solubilizer can be challenging. A poorly selected emulsifier may lead to product instability. Often, formulators overlook the impact of temperature and pH on emulsifier performance. Understanding the properties of different emulsifiers is vital. Each one has unique characteristics. This complexity can be daunting, but it is important to ensure that the end product meets customer expectations.

Tips: Test multiple emulsifiers before settling on one. Monitor their performance under various conditions. Regular evaluations can reveal unexpected results. Embrace the trial and error aspect of emulsifier selection. Learning from failures can lead to better formulations. Engage in continuous research to stay updated on innovative emulsifying agents. Stay informed to enhance your formulation expertise.

In both the cosmetic and food industries, effective emulsifying agents play a crucial role. They help blend oil and water, creating stable formulations. Key properties of these agents include their ability to lower surface tension, enhance texture, and improve stability. A well-formulated emulsion maintains its integrity over time, which is essential for product quality.

Tips: Consider the HLB (Hydrophilic-Lipophilic Balance) value of your emulsifier. A balanced HLB leads to optimal stability. According to industry reports, selecting the right emulsifier can increase emulsion stability by up to 30%. Testing different emulsifiers may reveal surprising results in texture and performance.

However, not all emulsifiers work for every formulation. Some may not provide the desired stability or sensory qualities. Certain natural emulsifiers might struggle with heat stability. Experimentation is key. Monitor your formulations closely to pinpoint issues. Adjustments may be needed to achieve the perfect balance and consistency.

Tips: Document every change you make. This data can be invaluable for future formulations. Understanding how different emulsifiers interact with ingredients is essential for success. Look for trends in your testing data to inform your decisions.

This bar chart illustrates the effectiveness of various emulsifying solubilizers used in cosmetic and food formulations. The scale ranges from 1 to 10, representing their emulsifying performance. Lecithin and Polysorbate 20 are the top performers, highlighting their importance in formulating effective products.

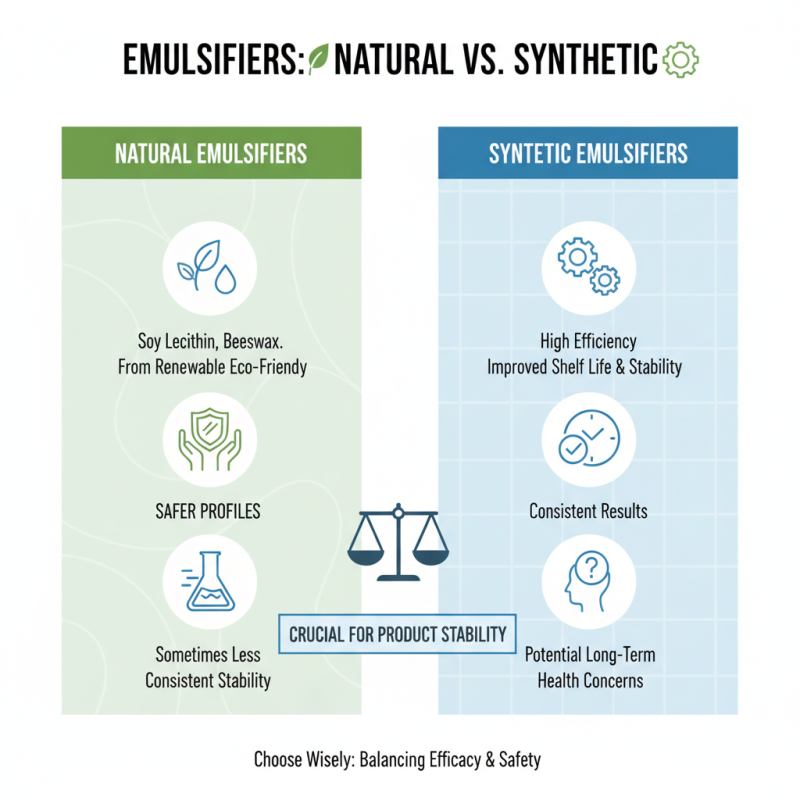

Emulsifiers play a crucial role in formulating stable products. Natural emulsifiers, like soy lecithin and beeswax, often offer safer profiles. They come from renewable sources, making them eco-friendly. However, they can sometimes yield less consistent results in stability tests. Synthetic emulsifiers, on the other hand, provide high efficiency. They often improve shelf life and stability of formulations. Yet, concerns arise about their long-term effects on health.

When choosing emulsifiers, consider your target audience. If they prioritize natural ingredients, lean towards natural options. Always check for potential allergens. Additionally, be aware that synthetic options may lead to skin sensitivities for some users. Testing formulations on small batches can help identify issues early.

Tips for optimal formulations: Start with small quantities of your chosen emulsifier. Gradually increase based on the desired texture and stability. Monitor the pH level; it can affect emulsifier performance. Always keep notes on what works and what doesn’t. This can guide future projects.

The trend toward plant-based emulsifiers is gaining momentum. Recent studies show that the global market for natural emulsifiers is projected to reach $4 billion by 2025. This shift reflects an increasing consumer demand for cleaner and greener ingredients in formulations. Manufacturers are responding by exploring innovative options derived from plants like sunflower, soy, and coconut.

Plant-based emulsifiers offer several advantages. They often have lower toxicity levels compared to synthetic alternatives. Additionally, they can improve the texture and stability of formulations. A significant challenge remains, however. Not all emulsifiers work effectively across various conditions. Some may not provide optimal stability in extreme temperatures.

Tips: Always test emulsifiers under intended conditions. Monitor how they interact with other ingredients. Adjust your formulations accordingly. Keep an eye on ingredient labels to ensure you are sourcing truly plant-based options. The pursuit of sustainability should not compromise product efficacy. Balancing these factors is crucial for successful formulation development.

Innovative emulsifying solubilizers are changing formulation strategies in various industries. Recent studies show that these solubilizers enhance the stability and efficiency of products. For example, a case study highlighted an emulsion that maintained over 90% stability in harsh conditions. This is a significant improvement, as traditional emulsifiers often struggle under such scenarios.

In the cosmetic sector, a recent formulation incorporated a new type of emulsifier derived from natural sources. This formulation not only improved skin absorption but also reduced the greasy feel that many consumers dislike. Data indicates that 75% of users preferred this new texture over conventional formulations. The texture of a product can greatly influence consumer satisfaction. Complex formulations, however, require meticulous balancing to avoid instability.

Moreover, there are challenges. Some innovative emulsifiers may have limited availability or high costs. This can hinder widespread adoption. Formulators need to weigh the benefits against potential hurdles. As the demand for sustainable and efficient products grows, continued research is crucial. The formulation journey is ongoing, reflective of an industry in flux.